H high strength and lightweight carbon fiber roller

The carbon fiber roller is processed and produced by advanced multi-layer winding molding process, and the materials are mainly imported from Japan T500 and T700 with high strength

The high modulus carbon fiber yarn is made by a special process of winding and weaving.

Carbon fiber roller is one of the key components for the future development of high-speed and wide-width growth machinery manufacturing industry. We will continue to develop new carbon fibers

Guide rollers to meet the special requirements of different high-speed and wide-format customer equipment.

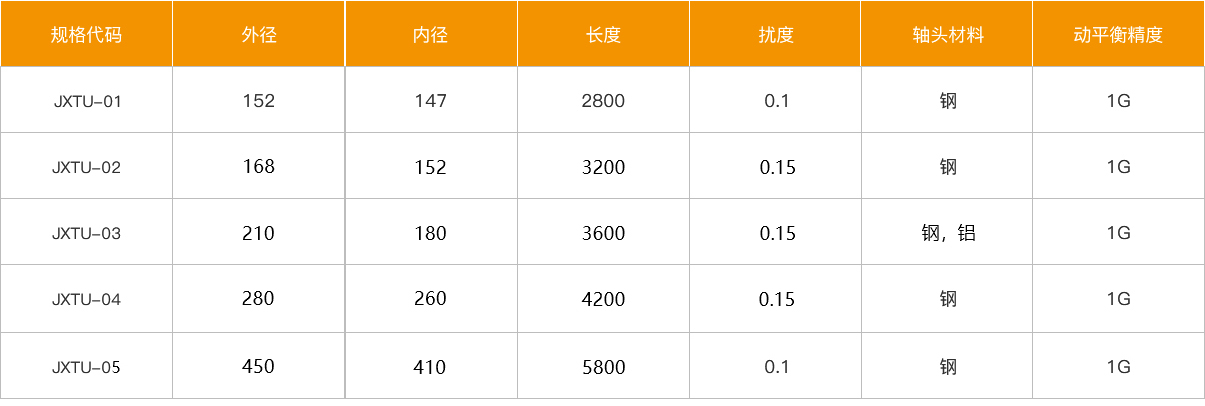

Carbon Fiber Roller Mould Specification Sheet

Features of Carbon Fiber Roller

● Light weight, the density is only one-fifth of steel, and the whole roller is about one-tenth of the original steel series

● Long service life, carbon fiber material has good fatigue strength, long-term use will not cause deformation, and the surface is stable without repeated processing.

● Good friction resistance.

● The friction coefficient of carbon fiber is only one twentieth of that of steel, and the surface hardness is high, so the surface of the product will not wear after long-term use.

● Carbon fiber rollers are light in weight and have high dynamic balance accuracy, which can greatly increase the speed and increase the production capacity of production equipment by more than 30%.

● Energy saving, due to its light weight, it can reduce the energy consumption of the equipment.

Parameters of carbon fiber rollers

Other performance descriptions of carbon fiber composites

● Resistant to 30% nitric acid and 50% alkali.

● Surface resistance 1.6x10-3 ohm cm2.

● The flame retardant time is less than 1 second.

● Good processing performance, suitable for turning and grinding.

● Thermal deformation coefficient 2.3X10-12/k.mm.